Key Benefits and Safety Tips for Welding Galvanized Wire

Zinc Layer Protection: The zinc layer on the surface of galvanized wire can still provide anti-corrosion protection for the welded parts to a certain extent after welding. Zinc, as an active metal, forms a dense oxide film in the air, preventing oxygen and moisture from coming into contact with the internal metal, thus delaying the occurrence of corrosion.

2025/01/13

Key Safety Measures for Shipping Galvanized Wire Locally

Based on factors such as the specifications, length, and weight of the galvanized wire, choose suitable packaging materials like plastic films, woven bags, or moisture

Keywords:

2025/01/10

A Guide to Selecting Galvanized Wire: Common Zinc or High Zinc?

When choosing between common zinc and high zinc galvanized wire, you can consider the following factors:

Keywords:

2025/01/09

Guide to Galvanized Wire: Crafting Specifications and Important Safety Tips

The following are the specifications and precautions for galvanized wire in the production of craft wire:

Keywords:

2025/01/08

The inner diameter of 350-500mm and the outer diameter of 450-1000mm of the large roll galvanized wire have the following advantages and reasons:

Keywords:

2025/01/07

Best Advantages of Round Galvanized Wire Over Flat Wire

In galvanized wire, the advantages of round wire over flat wire are mainly reflected in the following aspects:

Keywords:

2025/01/06

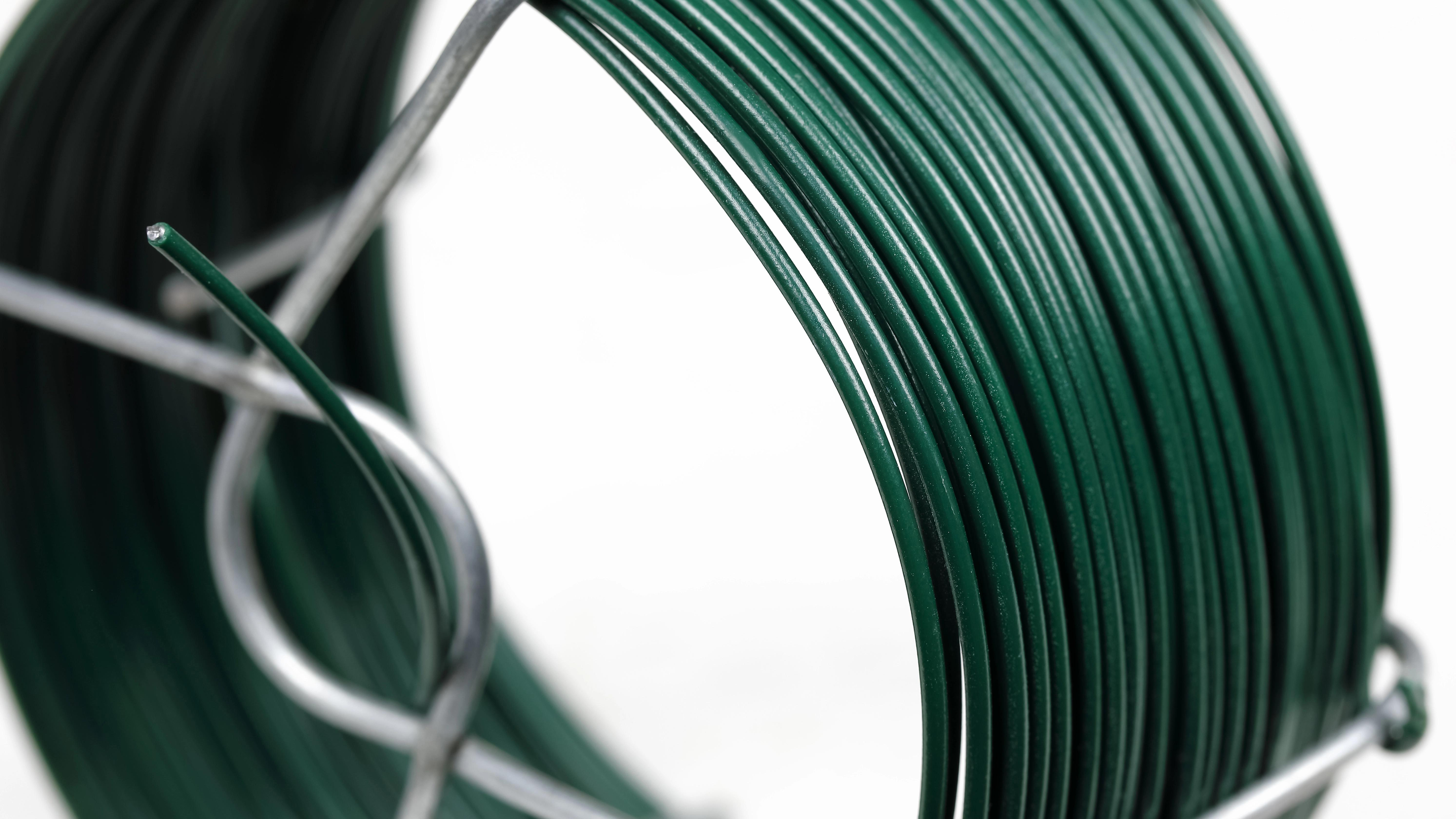

Understanding the Material Process Differences Between PVC Coated and PE Coated Wire

The main raw material is polyvinyl chloride (PVC). PVC is an amorphous thermoplastic with good plasticity, chemical corrosion resistance, and electrical insulation. It can be easily processed into various forms under appropriate temperature and pressure conditions.

Keywords:

2025/01/03

The wire diameter generally ranges from 2.0 mm to 4.0 mm. For example, in some small - scale landscape projects or temporary protection works, a wire diameter of 2.0 - 2.5 mm might be sufficient. In large - scale hydraulic engineering and other projects with high - strength requirements, a diameter of 3.0 - 4.0 mm is often used. The tolerance of wire diameter is usually controlled within ±0.05 mm - ±0.08 mm.

Keywords:

2025/01/02

More information